Floating Connectors / Miniature Type (Part Numbers - CAD Download)

- Volume Discount

- Order quantities extended (D-JIT)

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

- Drawing / Specifications

- 3D Preview 3D preview is available after complete configuration

- Part Numbers

- More Information

- Catalog

FLCM

| [M] Material | [A] Accessory | |

| Main Body | See below | Hex Nut (Trivalent Bright Chromate) |

| Socket (Tapped) | EN CW614N Equiv. | |

| Bolt (Threaded) | EN 1.4301 Equiv. |

Specification Table

| Part Number |

| FLCM3−0.5 |

| Part Number | ℓ | ℓ1 | ℓ2 | ℓ3 | L | T | D | B | B1 | B2 | (C) | (C1) | (C2) | Allowable Misalignment U | Working Load kgf (N) | Mass (g) | |

| Type | M-Pitch | ||||||||||||||||

| FLCM | 3-0.5 | 4.5 | 8 | 8 | 3 | 12 | 1.8 | 11 | 11 | 5.5 | 5.5 | 12.7 | 6.4 | 6.4 | 0.5 | Up to 1.9 (19) | 8 |

| 4-0.7 | 10 | 10 | 4 | 2.4 | 7 | 7 | 8.1 | 8.1 | Up to 5.4 (53) | 9 | |||||||

| 5-0.8 | 6 | 11 | 12.5 | 17 | 3.2 | 14 | 14 | 8 | 6 | 16.2 | 9.2 | 7 | Up to 12.3 (121) | 21 | |||

| 6-1.0 | 14 | 15.5 | 3.6 | 10 | 11.5 | 22 | |||||||||||

Part Number:

- In order to open the 3D preview, the part number must be fixed.

3D preview is not available, because the part number has not yet been determined.

Loading...

Part Number

|

|---|

| FLCM3-0.5 |

| FLCM4-0.7 |

| FLCM5-0.8 |

| FLCM6-1.0 |

| Part Number |

Standard Unit Price

| Minimum order quantity | Volume Discount | Max. Operating Pull Compression Force (kN) | |

|---|---|---|---|---|---|

38.41 € | 1 | Available |

Same day

Stock | 0.019 | |

39.04 € | 1 | Available |

Same day

Stock | 0.053 | |

40.30 € | 1 | Available |

Same day

Stock | 0.121 | |

41.68 € | 1 | Available |

Same day

Stock | 0.121 |

Loading...

·The tip inside the connector is spherical, and absorption of misalignment is possible. Shaft alignment and parallelism setting in cylinder mounting can thus be achieved merely by visual estimation.

·Due to integration of connector and holder, selecting is easy, and at the same time, number of parts is reduced.

·For Miniature Type (FLCM), screws with sizes M3 to M6 are provided for small cylinders.

·For Standard Type, three mounting variations are offered: Screw-In Type (FLCT), Flange Mounting Type (FLCF) and Bracket Mounting Type (FLCL).

■ Components

| Thread Dia. | Type (Mounting Method) | |

| Miniature | M3 to M6 | FLCM (Screw-In) |

| Standard Type | M8 to M26 | FLCT (Screw-In), FLCF (Flange Mounting), FLCL (Bracket Mounting) |

Miniature (M3 to M6)

FLCM

FLCM

| Part No. | Part Name | Material | Surface Treatment |

| (1) | Stud | EN 1.4301 Equiv. | — |

| (2) | Nut | JIS−SWRM8 | Trivalent Bright Chromate |

| (3) | Case | EN CW614N Equiv. | — |

| (4) | Ball Holder | EN CW614N Equiv. | — |

| (5) | Ball Joiner | EN CW614N Equiv. | — |

| (6) | Socket | EN CW614N Equiv. | — |

| (7) | Thin Nut | JIS−SWCH | Trivalent Bright Chromate |

Standard Type (M8 to M26)

FLCT·FLCF·FLCL

FLCT·FLCF·FLCL

| Part No. | Part Name | Material | Surface Treatment |

| (1) | Socket | EN 1.0736 Equiv. (M26 is EN 1.1191 Equiv.) | Trivalent Bright Chromate |

| (2) | Cap | EN 1.3505 Equiv. | — |

| (3) | Case | EN 1.0480 Equiv. (FLCT: M22 to M26 is EN−JL 1030 Equiv.or EN−JL 1040 Equiv.) (FLCF/FLCL: M14 to 26 is EN−JL 1030 Equiv.or EN−JL 1040 Equiv.) | Trivalent Bright Chromate (FLCT: M22 to M26 is Manganese Phosphate Coating) (FLCF/FLCL: M14 to 26 is Manganese Phosphate Coating) |

| (4) | Ball Joiner | EN 1.1191 Equiv. | — |

| (5) | Ball Holder | EN 1.3505 Equiv. | — |

| (6) | Rubber Steel Ball Retainer Plate | Nitrile Rubber | — |

| (7) | Steel Ball | EN 1.3505 Equiv. | — |

| (8) | Base Plate | EN 1.3505 Equiv. | — |

■ Features

·Misalignment is absorbed in three-dimensions through the ball joint swing A and misalignment motion B. (See Fig.1)

·FLCT, FLCF and FLCL have a built-in bearing, which reduces lateral load significantly and absorbs misalignment. (See Fig. 2)

■ Benefits

The following benefits are obtained by installing on the cylinder rod.

·Prevents one end of cylinder rod from getting worn out.

·Prevents breakage of the gasket, enables low pressure operation, prevents thrust drop

■ Precautions for Use

·Although the screw is rotatable, the connector cannot be used as a rotating joint.

·Non-reusable after disassembled. ·Grease filled to eliminate oiling.

·The applied load shown is static. Note that the applied load value for repeated impact load will be lower than shown.

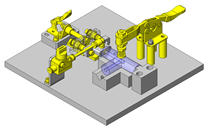

■ App. Example

Basic information

| Connection Type, Cylinder Side | Tapped | Allowable Misalignment U(mm) | 0.5 | Allowable Angular Deviation (A°)(deg) | ±5 |

|---|---|---|---|---|---|

| Surface Treatment | Black Oxide |

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Complementary Products

MISUMI Unit еxample related to this product

Tech Support

- Technical Support

- Tel:+49 69 668173-0 / FAX:+49 69 668173-360

- Technical Inquiry