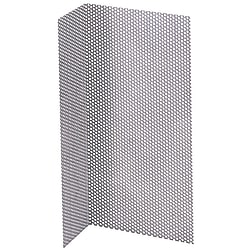

Perforated Metal / L-Shaped

- Order quantities extended (D-JIT)

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

- Drawing / Specifications

- 3D Preview 3D preview is available after complete configuration

- Part Numbers

- Catalog

Dimensional Drawing

PMSL·PMUL

PMSU·PMUU

[ ! ] Hole positions on cut surface cannot be specified (The curved section doesn't always have holes).

| T | A, B Tolerance | W Tolerance | H Tolerance |

| 0.5 | ±0.5 | ±1.0 | ±0.5 |

| 0.8 | ±0.8 | ±1.6 | ±0.8 |

| 1.0 | ±1.0 | ±2.0 | ±1.0 |

| Type | [M] Material | [S] Surface Treatment | |

| L-Shaped | U-Shaped | ||

| PMSL | PMSU | EN 1.0330 Equiv. | Nickel Plating |

| PMUL | PMUU | EN 1.4301 Equiv. | — |

Specification Table

| Part Number | 1 mm Increments | T Selection | P | Perforated Rate % | ||||

| Type | D | A | B | L | PMSL | PMUL | ||

| PMSL PMUL | 1 | 30 to 200 | 30 to 200 | 30 to 300 | 0.5 0.8 | 0.5 0.8 | 2 | 22.6 |

| 2 | 0.5 0.8 1.0 | 1.0 | 3 | 40.2 | ||||

| Part Number | 1 mm Increments | T Selection | P | Perforated Rate % | ||||||||

| Type | D | W | H | L | PMSU | PMUU | ||||||

| PMSU PMUU | 1 | 60 to 200 | 30 to 100 (H ≤ W/2) | 30 to 300 | 0.5 | 0.8 | 0.5 | 0.8 | 2 | 22.6 | ||

| 2 | 0.5 | 0.8 | 1.0 | 1.0 | 3 | 40.2 | ||||||

| Part Number | — | A | — | B | — | L | — | T |

| PMUL2 | — | 100 | — | 50 | — | 200 | — | 1.0 |

| Part Number | — | W | — | H | — | L | — | T |

| PMSU1 | — | 120 | — | 60 | — | 200 | — | 0.8 |

Alterations

| Part Number | — | A | — | B | — | L | — | T | — | (XC·XWC·XTC) |

| PMSL1 | — | 100 | — | 70 | — | 200 | — | 0.8 | — | XC4.5−F45−G15 |

| Part Number | — | W | — | H | — | L | — | T | — | (XWC·XTC) |

| PMSU2 | — | 120 | — | 60 | — | 85 | — | 1.0 | — | XWC4.5−F25−G10 |

| Alterations | 2 Mounting Holes | 4 Mounting Holes | 6 Mounting Holes | ||||||

| ·L-Shaped ·U-Shaped | ·L-Shaped ·U-Shaped | |||||||

| Code | XC | XWC | XTC | ||||||

| Spec. | * Adds 2 mounting holes. XC = Hole Dia. Selection F, G = 1 mm Increments Ordering Code XC4.5−F45−G15 [ ! ] Hole Dia. Selection Table

[ ! ]XC/2+3 ≤ G ≤ (A−T) −XC/2−6 [ ! ] Applicable to L-shaped type only | * Adds 4 mounting holes. XWC = Hole Dia. Selection F, G = 1 mm Increments Ordering Code XWC4.5−F55−G12 [ ! ] Hole Dia. Selection Table

·L-Shaped Type [!] XWC + 3 ≤ G ≤ [A (B) - T] - XWC/2 - 6 ·U-Shaped Type [!] XWC/2 + 3 ≤ G ≤ (H - T) - XWC/2 - 6 | * Adds 6 mounting holes. XTC = Hole Dia. Selection F, G = 1 mm Increments Ordering Code XTC5.5−F25−G15 [ ! ] Hole Dia. Selection Table

·L-Shaped Type [!] XTC + 3 ≤ G ≤ [A (B) - T] - XTC/2 - 6 ·U-Shaped Type [!] XTC/2 + 3 ≤ G ≤ (H - T) - XTC/2 - 6 |

Part Number:

- In order to open the 3D preview, the part number must be fixed.

3D preview is not available, because the part number has not yet been determined.

| Part Number | Minimum order quantity | Volume Discount | RoHS | Material | Specifications | Punch Hole Dia. D (φ) | A (mm) | B (mm) | L (mm) | T (mm) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 9 Days | 10 | EN 1.0330 Equiv. | L-Shaped Type | 1 | 30 ~ 200 | 30 ~ 200 | 30 ~ 300 | 0.5 ~ 0.8 | ||

| 1 | 9 Days | 10 | EN 1.0330 Equiv. | L-Shaped Type | 2 | 30 ~ 200 | 30 ~ 200 | 30 ~ 300 | 0.5 ~ 1 | ||

| 1 | 9 Days | 10 | EN 1.0330 Equiv. | U-Shaped Type | 1 | 60 ~ 200 | 30 ~ 100 | 30 ~ 300 | 0.5 ~ 0.8 | ||

| 1 | 9 Days | 10 | EN 1.0330 Equiv. | U-Shaped Type | 2 | 60 ~ 200 | 30 ~ 100 | 30 ~ 300 | 0.5 ~ 1 | ||

| 1 | 9 Days | 10 | EN 1.4301 Equiv. | L-Shaped Type | 1 | 30 ~ 200 | 30 ~ 200 | 30 ~ 300 | 0.5 ~ 0.8 | ||

| 1 | 9 Days | 10 | EN 1.4301 Equiv. | L-Shaped Type | 2 | 30 ~ 200 | 30 ~ 200 | 30 ~ 300 | 1 | ||

| 1 | 9 Days | 10 | EN 1.4301 Equiv. | U-Shaped Type | 1 | 60 ~ 200 | 30 ~ 100 | 30 ~ 300 | 0.5 ~ 0.8 | ||

| 1 | 9 Days | 10 | EN 1.4301 Equiv. | U-Shaped Type | 2 | 60 ~ 200 | 30 ~ 100 | 30 ~ 300 | 1 |

Loading...

Configure

Basic Attributes

-

Material

- EN 1.0330 Equiv.

- EN 1.4301 Equiv.

-

Specifications

- L-Shaped Type

- U-Shaped Type

-

Punch Hole Dia. D(φ)

- 1

- 2

-

A(mm)

-

B(mm)

-

L(mm)

-

T(mm)

-

Type

- PMSL

- PMSU

- PMUL

- PMUU

-

Filter by CAD data type

- 2D

- 3D

Filter by standard shipping days

-

- All

- 9 Days or Less

Optional Attributes

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Complementary Products

Tech Support

- Technical Support

- Tel:+49 69 668173-0 / FAX:+49 69 668173-360

- Technical Inquiry