Welding Clamp - Flange Base

- Promotional pricing

- Volume Discount

- Order quantities extended (D-JIT)

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

- Drawing / Specifications

- 3D Preview 3D preview is available after complete configuration

- Part Numbers

- More Information

- Catalog

MC09-1

| MC09-2 | MC09-3 |

|  |

Specification Table

| Part Number |

| MC09−1 |

| Part Number | MC09−1 | MC09−2 | MC09−3 |

| Body Material | EN 1.0038 Equiv. (with Hardened Bushing) | ||

| Weight (g) | 845 | 2130 | 4100 |

| Tightening Force (N) | 1960 | 4900 | 9800 |

| Handle Movement Angle | 120° | 124° | 126° |

| Arm Movement Angle | 193° | 193° | 198° |

Part Number:

- In order to open the 3D preview, the part number must be fixed.

3D preview is not available, because the part number has not yet been determined.

Loading...

Loading...

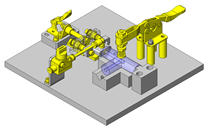

App. Example

How to Use Welding Clamps for Various Applications | Welding Clamps are composed of 4 parts shown to the left; handle, main body, base and arm. (1) Determine the mounting position of the main body. (2) Determine the length of the control arm, then connect to the body arm by welding. (3) Considering the space from the fixture for clamp mounting, determine the height of the handle, and weld the handle and the body handle receiver. (4) Determine the angle between the main body and the supporting plate, and connect them by welding. (5) Determine how to mount a clamp on to the fixture. If the base is used, weld the base and the supporting plate together. Assemble a welding clamp as described above. ● Welding Clamps can be flexibly assembled depending on different working situations, thus can be used in wide range of applications. ● Heat treatment (hardness 60 HRC) ensures abrasion-resistant assembly of the pin constituting the supporting point, and the surrounding bushing. The clamps are best for fixtures that require frequent use or accuracy. |

Basic information

| Attaching Method | Flange Base | Body Material | EN 1.0038 Equiv. | Handle Length | Standard |

|---|

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

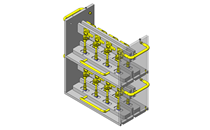

Complementary Products

MISUMI Unit еxample related to this product

Tech Support

- Technical Support

- Tel:+49 69 668173-0 / FAX:+49 69 668173-360

- Technical Inquiry

![[Precision] X-Axis / Cross Roller](http://content.misumi-ec.com/image/upload/f_auto,t_product_recommend_a/v1/p/jp/product/series/110300196460/110300196460_001.jpg)