Long Panel Support Brackets (Aluminum)

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

- Drawing / Specifications

- 3D Preview 3D preview is available after complete configuration

- Part Numbers

- Catalog

- Technical Information

HCBAL6S

HCBAL8

* When Alteration CTW45 is specified, the M5 Mounting Hole will be provided at 20 mm from the end.

[S]Surface Treatment: Clear Anodize

Specification Table

| Part Number | — | L |

| HCBAL6 | — | 1000 |

| Part Number | L 1 mm Increments | Difference between the Extrusion Side and Attachment Face | S | Applicable Screws and Nuts | ||||

| Type | No. | Screw | Quantity | Nut | Quantity | |||

| HCBAL | 6 | 50 to 2000 | 5 | 10 | CBM6-12 | 2 | HNTT6-6 | 2 |

| 6S | 3 | 12 | ||||||

| 8* | 5*2 | 15 | CBM6-15 | HNTT8-6 | ||||

[ ! ] Use Panel Mounting Screws for panel mounting.

Alterations

| Part Number | — | L | — | (CTW45·MH) |

| HCBAL6 | — | 500 | — | CTW45 |

| HCBAL8 | — | 700 | — | MH |

| Alteration | Code | Spec. |

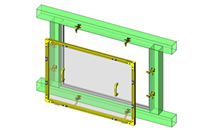

| Panel Brackets Aluminum - Long Cut 45 Degrees on Upper Slot | CTW45 | Panel Support Bracket Aluminum Long Type at both ends at 45 degrees Cut. ■ Mounting Example  |

| One Mounting Hole Addition | MH | Adds one M5 mounting hole on the middle of L Dimensions. |

Product Overview (Panel Clamp Overview)

It is possible to add a hole in the middle and attach Panel Brackets for reinforcement.

Panel Brackets are tapped hole machined.

■Panel Brackets Type

| Product Name | Panel Brackets | Panel Clamps Bracket | |||

|---|---|---|---|---|---|

| Plastic | Aluminum Type | Length Configuration Aluminum - Long | Steel, Stainless Steel | ||

| Image |

|

|

|

|

|

| App. Example |

|

|

|

|

|

| Descriptions | Easy installation by inserting the T-shaped stopping part into the slot and turning 90. Applicable to both 3 mm and 5 mm thick panels. | An aluminum type Panel Bracket that is fixed to the extrusion using screws and nuts. | The clearance between the extrusion and panel can be filled. You can also use it for reinforcements. | Steel, stainless steel panel brackets. | Easy installation by inserting the T-shaped stopping part into the slot and turning 90. Applicable to both 3 mm and 5 mm thick panels. Hole machining on the panel is not required. |

App. Example

The gap between the extrusion and panel can be filled.

Use for reinforcements also.

Bracket Mounting

■ Overview

Mounting panels on brackets within the extrusions.

This results in aesthetically good appearance, and makes for easy install/remove of the panels. Recommended for Safety Covers, etc.

When using eccentric bracket HBLTH5, it will be flush with the extrusion.

It is possible to install a panel with a length of 5 mm or more, but it will protrude from the aluminum extrusion surface.

| App. Example | Precision equipment frames, production equipment for food and medicine improvement |

|---|---|

| Ease of Panel Removal | × |

| Gap between Panels and Extrusions | No |

| Appearance | Excellent |

| Panel Size Calculations | Calculations needed for the corners*4 |

| Panel Thickness (mm) | 3 mm (5/6 Series) |

| 5 mm (5/6/8/8-45 Series) |

■Mounting Method

(1) Tapping is specified for the brackets. (Example: HBLTS6-C)This must be specified when ordering the bracket.

(2) Fasten the panel with the cover mounting screws.

* If the panel is large, you can strengthen it by using a panel bracket in the middle.

How to Select Parts

| Component | (1) Aluminum extrusion | (2) Aluminum extrusion | (3) Bracket | (4) Screw | (5) Panel | ((6) Panel Support Bracket) |

|---|---|---|---|---|---|---|

| Part Number Example | HFS6-3030-400 | HFS6-3030-340 | HBLFSN6-C-SET | HCBM5-8 | ACAE4H-336-336 -5-F316-G316-N5 | HCBA6-SET |

| Quantity | 2 | 2 | 4 | 4 | 1 | As needed |

(1) Aluminum extrusion: No Alterations

(2) Aluminum Extrusion: No Alterations

(3) Bracket: Tapping (M5)

(4) Screw: Match the hole diameter of the bracket.

(5) Panel: Hole Machining (M5)

Size

Leave a clearance of 1 mm on each side.Panel width (A) = Frame internal dimension (L1) - Clearance (2 mm)

Panel width (B) = Frame internal dimension (L2) - Clearance (2 mm)

Thickness

·For M5 (5 Series) Extrusions: 3 mm Thick·For M6 and M8 (6, 8(-45) Extrusions: 5 mm Thick

A = L1 (400-30-30)-Clearance both ends (2 mm) = 338 mm

B = L2 (340)-Clearance both ends (2 mm) = 338 mm

5 mm thickness, 4 holes (M5)

↓

AXAE4H-336-336-5-F316-G316-N5

(6) Panel Brackets

Depending on the size of the panel, it is possible to add a hole in the middle and attach Panel Brackets for reinforcement.

Panel Brackets are tapped hole machined.

Part Number:

- In order to open the 3D preview, the part number must be fixed.

3D preview is not available, because the part number has not yet been determined.

Part Number

|

|---|

| HCBAL6-[50-2000/1] |

| HCBAL6S-[50-2000/1] |

| HCBAL8-[50-2000/1] |

| Part Number | Minimum order quantity | Volume Discount | RoHS | Extrusion No. | Difference between the Extrusion Side and Attachment Face | L (mm) | |

|---|---|---|---|---|---|---|---|

| 1 | 6 Days | 10 | 6 | 5 | 50 ~ 2000 | ||

| 1 | 6 Days | 10 | 6 | 3 | 50 ~ 2000 | ||

| 1 | 6 Days | 10 | 8 | 5 | 50 ~ 2000 |

Loading...

Basic information

| Material | Aluminum | Material | EN AW-6063-T5 Equiv. |

|---|

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .