Plates / NBR / A60 / through holes, countersunk holes / adhesive layer, oil resistant

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

- Drawing / Specifications

- 3D Preview 3D preview is available after complete configuration

- Part Numbers

- More Information

- Catalog

- Technical Information

Dimensional Drawing

[ ! ] The sheet can be cut at a desired dimensions regardless of the pattern.

V Pattern Width 11 mm Type

V Pattern Width 22 mm Type

·T Dimensional Tolerance: ±0.5

·Dimensional tolerance of A and B

| A, B Dimension | Tolerance |

| 200 or Less | ±0.5 |

| 300 or less | ±1.0 |

| Hole Machining Details | ||||||||||||||||

N (Through Hole) P (Countersunk)

| ||||||||||||||||

| No Adhesive | Adhesive | [M] Material | [H] Hardness | Color | |

| V Pattern Width 11 mm | STHVS | STHVSA | Nitrile Rubber Equivalent (Hyper V Oil Resistant Type) | Shore A60 | Black |

| V Pattern Width 22 mm | STHVM | STHVMA |

Specification Table

| Part Number | — | A | — | B |

| STHVS4 | — | 250 | — | 100 |

| Part Number | — | A | — | B | — | F | — | G | — | N |

| STHVS4H4 | — | 250 | — | 200 | — | F200 | — | G150 | — | N5 |

| Part Number | 1 mm Increments | ||

| Type | T | A | B |

| STHVS STHVSA | 4 | 10 to 300 | 10 to 300 |

| STHVM STHVMA | 4.5 | ||

| Part Number | 1 mm Increments | Screw Nominal Dia. Selection | ||||||

| Type | Nominal | T | A | B | F | G | N (Through Hole) | P (countersunk) |

| STHVS STHVSA | 2H 4H | 4 | 10 to 300 | 10 to 300 | 5 to 295 | 5 to 295 | 3·4·5 | 3 |

| STHVM STHVMA | 4.5 | |||||||

[ ! ] Dimension F Specification Range: d (d1 ) + 5 ≤ F ≤ A - d (d1 ) - 5, Dimension G Specification Range: for 2H: d (d1 )/2 + 2.5 ≤ G ≤ B - d(d1 )/2 - 2.5,

for 4H: d (d1 ) + 5 ≤ G ≤ B - d (d1 ) - 5.

Part Number:

- In order to open the 3D preview, the part number must be fixed.

3D preview is not available, because the part number has not yet been determined.

| Part Number | Minimum order quantity | Volume Discount | With or w/o Adhesive | Width A (mm) | Length B (mm) | Hole Machining | Countersink Hole Nominal Dia. [P] | F (mm) | G (mm) | Through Hole Nominal Dia. [N] | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 7 Days | No Adhesive | 10 ~ 300 | 10 ~ 300 | 2H (Two Holes) | - | 5 ~ 295 | 5 ~ 295 | 3 ~ 5 | ||

| 1 | 7 Days | No Adhesive | 10 ~ 300 | 10 ~ 300 | 2H (Two Holes) | 3 | 5 ~ 295 | 5 ~ 295 | - | ||

| 1 | 7 Days | No Adhesive | 10 ~ 300 | 10 ~ 300 | No Drilling Alteration | - | - | - | - | ||

| 1 | 7 Days | No Adhesive | 10 ~ 300 | 10 ~ 300 | 4H (Four Holes) | - | 5 ~ 295 | 5 ~ 295 | 3 ~ 5 | ||

| 1 | 7 Days | No Adhesive | 10 ~ 300 | 10 ~ 300 | 4H (Four Holes) | 3 | 5 ~ 295 | 5 ~ 295 | - | ||

| 1 | 7 Days | Adhesive | 10 ~ 300 | 10 ~ 300 | 2H (Two Holes) | - | 5 ~ 295 | 5 ~ 295 | 3 ~ 5 | ||

| 1 | 7 Days | Adhesive | 10 ~ 300 | 10 ~ 300 | 2H (Two Holes) | 3 | 5 ~ 295 | 5 ~ 295 | - | ||

| 1 | 7 Days | Adhesive | 10 ~ 300 | 10 ~ 300 | No Drilling Alteration | - | - | - | - | ||

| 1 | 7 Days | Adhesive | 10 ~ 300 | 10 ~ 300 | 4H (Four Holes) | - | 5 ~ 295 | 5 ~ 295 | 3 ~ 5 | ||

| 1 | 7 Days | Adhesive | 10 ~ 300 | 10 ~ 300 | 4H (Four Holes) | 3 | 5 ~ 295 | 5 ~ 295 | - |

Loading...

Specifications/Overview

characteristics

■Measurement of Skid Resistance Coefficient (Ono Field-Portable Slip Test)

| Condition | Skid Resistance Coefficient (C. S. R’) | ||

| Hyper V Sheet | Rubber Plain Sheet | ||

| V22 Type | V11 Type | ||

| Dry | 0.97 | 0.98 | 0.76 |

| Wet (Water) | 0.8 | 0.84 | 0.42 |

| Wet (Glycerin) | 0.31 | 0.44 | 0.03 |

Measure Max. Tensile Load (N) = Pmax by pulling a test specimen of 5 mm thickness

with applying 200N load on a stainless steel sheet of 50 mm × 60 mm.

A test result is shown as C.S.R' = Pmax/W.

Recommended as a rubber mat or a chucking material for workpieces that are slippery by cutting oil.

Simple Illustration of Ono Field-Portable Slip Test

The test result shows that V22 Type begins moving by the force of 62N, V11 Type by 88N

and the Plain Sheet by 6N with glycerin coating. It proves that Hyper V has an excellent slip resistance property.

App. Example

General Information - Panels (polyurethane rubber, rubber, foam, felt)

_-_Sortiment.jpg)

Selection details of panels (polyurethane rubber, rubber, foam, felt)

- Material: polyurethane rubber (PU/PUR), heat-resistant polyurethane rubber, low-impact polyurethane rubber, abrasion-resistant polyurethane rubber, antistatic polyurethane, nitrile (NBR), chloroprene rubber (CR), polyethylene (EPDM), silicone (SI), fluorine (FPM), butyl rubber (IIR), natural rubber (NR), hard rubber, special synthetic rubber, polyurethane foam, head-insulating foam, polyethylene foam, low-rebound foam

- Thickness (mm): 0.5 to 50

- Width (mm): 3 to 500

- Length (mm): 10 to 2000

Description/Basics

Foam plates and rubber plates are provided for damping or for sound proofing. MISUMI offers these in various Shore hardening for a wide variety of tasks. Due to the variety of materials, different resistances to environmental influences are possible depending on the application. The foam plates reduce sound in machines and can reduce the sound emissions of a system. For more information on foam characteristics, follow this link.

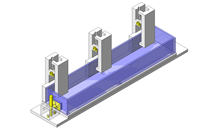

Rubber plates or foam plates are also suitable in conveyor systems to absorb components to be transported at a dampened level or to protect them from damage as a lateral guide when the components bump into each other. Hard rubber panels or low-impact rubber or foam panels reduce the impact energy of the components. These minimize and lower the vibrations in an application.

In addition, MISUMI offers highly abrasion-resistant polyurethane (Vulkollan), which has an abrasion resistance that is six times higher than with conventional polyurethane.

Ceramic polyurethane plates contain ceramic particles. After machining, these can have a smooth surface despite low Shore hardness.

The polyurethane rubber plates are also available antistatically. The specific resistance of antistatic polyurethane plates prevents static charging. This prevents any damage to electronic components.

For applications with higher temperatures, MISUMI offers heat-resistant polyurethane rubber, which can withstand a temperature range of up to approx. ~120°C (see the product specifications for exact information).

MISUMI also offers low-friction and anti-friction rubber plates. Low-friction rubber plates are often used in the gentle component guide for belt conveyors and roller conveyors.

Felt plates have the property of absorbing or dispensing oil and other liquids via the capillary effect. This property can be used to remove, for example, excess oil on a belt conveyor.

In addition, MISUMI offers rubber plates and foam plates that are self-adhesive for simplified assembly. Furthermore, you will find double-adhesive tape for attaching rubber plates and foam plates.

Additional properties on foam panels and rubber plates can be found in the Properties PDF.

MISUMI also offers these products in a round shape as discs and sleeves made of rubber, natural rubber, foam and felt.

Application Examples - Panels (polyurethane rubber, rubber, foam, felt)

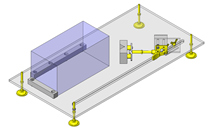

Application example

(1) Low-friction rubber plate (2) belt conveyor

Application example

(1) Vibration damping plate

Industrial Applications

Basic information

| Material | Rubber | Grade, Type | NBR Equiv. (Hyper V Oil Resistant Type) | Thickness T(mm) | 4 |

|---|---|---|---|---|---|

| Specifications | A, B Configurable / V Pattern Width 11mm |

Configure

Basic Attributes

-

With or w/o Adhesive

- Adhesive

- No Adhesive

-

Width A(mm)

-

Length B(mm)

-

Hole Machining

- 2H (Two Holes)

- 4H (Four Holes)

- No Drilling Alteration

-

Countersink Hole Nominal Dia. [P]

-

F(mm)

-

G(mm)

-

Through Hole Nominal Dia. [N]

-

Type

- STHVS

- STHVSA

- STHVSA□H

- STHVS□H

-

Filter by CAD data type

- 2D

- 3D

Optional Attributes

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Frequently Asked Questions (FAQ)

-

Question:

How can you attach a rubber plate?

-

Answer:

A rubber plate can be attached with double-adhesive tape. MISUMI offers rubber plates with configurable through holes or counterbores with adhesive tape.

-

Question:

Do you have screw-on rubber panels?

-

Answer:

MISUMI offers rubber plates that can be screwed on via a through hole or counterbore. The rubber plates with counterbores are well suited for applications that need to form a flat surface.

-

Question:

Is NBR oil-resistant?

-

Answer:

The NBR rubber is oil-resistant and is often used as a sealing material for rubber or foam. In addition, NBR has good thermal resistance, which in combination with high abrasion resistance is the best suited NBR material for seals.

-

Question:

Which material reduces vibrations well?

-

Answer:

Silicone gel vibration dampers reduce vibrations well. This elastic material reduces the transmission of vibrations to the subsequent component and also contributes to the acoustics.

-

Question:

What is Vulkollan?

-

Answer:

Vulkollan is a highly abrasion-resistant polyurethane rubber that has high wear resistance. It is one of the high-performance rubbers that has little pressure deformation and can withstand high impact forces. In addition, Vulkollan has a high tear strength. However, over time Vulkollan may change its colour, but without losing its mechanical properties.