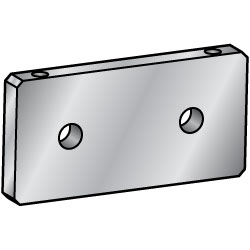

6 Surface Milling Machine Plates/Brackets. Side Hole Type. VFMQA

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

- Drawing / Specifications

- 3D Preview 3D preview is available after complete configuration

- Part Numbers

- Catalog

- Technical Information

[ ! ] Hole pitch dimension tolerance conforms to JIS B 0405 Class m.

[ ! ]Green colored parameters can be omitted.

If the parameter setting is omitted, the holes will be evenly distributed about the center.

Hole Type | Tapped Hole | Bolt Hole | Counterbore Front | Counterbore Back | |||||||||||||||||||||||||||||||||||

Code | M·MA | N・NA | Z·ZF | ZB | |||||||||||||||||||||||||||||||||||

Shape Diagram |  |  |  |  | |||||||||||||||||||||||||||||||||||

Machining Specifications | Effective Tap Length Max. M, MA × 2 [ ! ] When T ≥ M and MA × 3, tap pilot might not go through. |

| |||||||||||||||||||||||||||||||||||||

| ■Min. Thickness per Taps on Side | ■Machining Specifications [ ! ] Even if the holes and side taps interfere, they will be machined as specified. However, there may be some remaining burrs if interference exits. | |||||||||||||

| ||||||||||||||

| ■Machining Limits There are machining limits for thickness between hole and hole or between hole and end face. (Example: "b" on the drawing below) |  | |||||||||||||

| Part Number | [M] Material | [S] Surface Treatment | |

| Type | Material Symbol | ||

| VFMQA | SC | EN 1.1206 Equiv. | — |

| SCB | Black Oxide | ||

| SCM | Electroless Nickel Plating | ||

| AM | EN AW-5052 Equiv. | — | |

| AMW | Anodize (Clear) | ||

| AMB | Anodize (Black) | ||

| SU | EN 1.4301 Equiv. | — | |

Specification Table

| Part Number | — | A | — | B | — | T | — | X | — | V | — | Hole Specification (1) Code / Nominal Dia. | — | L | — | H | — | D | — | F | — | S | — | G | — | Hole Specification (2) Code / Nominal Dia. | ||

| Type | — | Material Symbol | ||||||||||||||||||||||||||

| VFMQA | — | AM | — | A50 | — | B30 | — | T5 | — | X10 | — | V30 | — | M4 | — | F40 | — | S20 | — | MA4 | ||||||||

| Part Number | 0.1 mm Increments | X | V | Hole Specification (1) | F | S | Hole Specification (2) | |||||

| Type | Material Symbol | A | B | T | Code | Nominal Dia. | Code | Nominal Dia. | ||||

| VFMQA | SC SCB SCM AM AMW AMB SU | 30.0 ~ 150.0 | 10.0 ~ 150.0 | 5.0 ~ 20.0 | Configurable 0.1 mm Unit | M | 0 (No Hole) 3 4 5 6 8 10 | 0.1 mm Increments | NA MA ZF ZB [ ! ] For the machining dimensions , see Hole Type Selection Chart. | 0 (No Hole) 3 4 5 6 8 10 12 16 | ||

Alteration

Part Number | A | B | T | X | V | Hole Specification 1 Code / Nominal Dia. | L | H | D (DC) | F | S | G | Hole Specification 2 Code / Nominal Dia. | (CC) | ||||||||||||||||

— | — | — | — | — | — | — | — | — | — | — | — | — | — | |||||||||||||||||

Type | — | Material Symbol | ||||||||||||||||||||||||||||

VFMQA | — | AM | — | A50 | — | B30 | — | T5 | — | X10 | — | V30 | — | M4 | — | F40 | — | S20 | — | MA4 | — | CC10 | ||||||||

Alterations | Corner Cut Change | ||

| |||

Code | CC | ||

Spec. | Changes corner cuts. CC = 1 mm Increments [ ! ]1 ≤ CC ≤ 20

|

Part Number:

- In order to open the 3D preview, the part number must be fixed.

3D preview is not available, because the part number has not yet been determined.

| Part Number | Minimum order quantity | Volume Discount | RoHS | Material | Surface Treatment | External Dimension A (mm) | External Dimension B (mm) | Plate Thickness t (mm) | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 7 Days | 10 | Aluminum Alloy 5000 series | Not Provided | 30 ~ 150 | 10 ~ 150 | 5 ~ 20 | ||

| 1 | 11 Days | 10 | EN AW-5052 Equiv. | Black Anodize | 30 ~ 150 | 10 ~ 150 | 5 ~ 20 | ||

| 1 | 11 Days | 10 | EN AW-5052 Equiv. | Clear Anodize | 30 ~ 150 | 10 ~ 150 | 5 ~ 20 | ||

| 1 | 7 Days | 10 | EN 1.1191 Equiv. | Not Provided | 30 ~ 150 | 10 ~ 150 | 5 ~ 20 | ||

| 1 | 9 Days | 10 | EN 1.1191 Equiv. | Black Oxide | 30 ~ 150 | 10 ~ 150 | 5 ~ 20 | ||

| 1 | 9 Days | 10 | EN 1.1191 Equiv. | Electroless Nickel Plating | 30 ~ 150 | 10 ~ 150 | 5 ~ 20 | ||

| 1 | 7 Days | 10 | EN 1.4301 Equiv. | Not Provided | 30 ~ 150 | 10 ~ 150 | 5 ~ 20 |

Loading...

Basic information

| Type | 6-Surface Milling | Part Mounting Hole | N/A | Slotted Hole | N/A |

|---|---|---|---|---|---|

| Side Hole | Yes | Number Of Holes | 4 | Type | With Side Surface Hole |

| Type | VFMQA |

Configure

Basic Attributes

-

Material

- EN AW-5052 Equiv.

- EN 1.1191 Equiv.

- EN 1.4301 Equiv.

- Aluminum Alloy 5000 series

-

Surface Treatment

- Black Anodize

- Black Oxide

- Clear Anodize

- Electroless Nickel Plating

- Not Provided

-

External Dimension A(mm)

-

External Dimension B(mm)

-

Plate Thickness t(mm)

-

Type

- VFMQA-AM

- VFMQA-AMB

- VFMQA-AMW

- VFMQA-SC

- VFMQA-SCB

- VFMQA-SCM

- VFMQA-SU

-

Filter by CAD data type

- 2D

- 3D

Filter by standard shipping days

-

- All

- 7 Days or Less

- 9 Days or Less

- 11 Days or Less

Optional Attributes

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Tech Support

- Technical Support

- Tel:+49 69 668173-0 / FAX:+49 69 668173-360

- Technical Inquiry