[Clean & Pack]Fittings for Vacuum Plumbing - JIS Flanged, VG Type (SL-FRVGA25A)

![[Clean & Pack]Fittings for Vacuum Plumbing - JIS Flanged, VG Type SL-FRVGA25A](http://uk.misumi-ec.com/linked/material/mech/MSM1/PHOTO/110310844289_001.jpg?$product_main$)

Product Details:

Manufacturer part number: SL-FRVGA25A

Brand: MISUMI

Price: 54.24 €

Delivery time: 7 Days

Technical Data:

Flange Shape: Standard

Flange Size (Nominal): 25

Cleaning Method: Degreasing

(i)Remark

- Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

SL-FRVGA25A

- Drawing / Specifications

- 3D Preview 3D preview is available after complete configuration

- Part Numbers

[ ! ] Maximum Operating Temperature: 200°C

| Type | [M] Material | Cleaning Method | ||||

| Blank Type | Hole Machined Type | Cleaning Method | Cleaning Environment | Packaging Type | Packing Environment | |

| SL-FRVG | SL-FRVGA | EN 1.4301 Equiv. | Degreasing | General Environment | Anti-Rust Packing | General Environment |

| SH-FRVG | SH-FRVGA | Precision Cleaning | Class 1,000* | Degassing Double Packing | Class 10** | |

| SHD-FRVG | SHD-FRVGA | Electrolytic polishing + precision cleaning | ||||

**US FED STD 209E, ISO 14644-1 ISO 4 Equiv.

[ ! ] Products are packed by order quantity. Ex. If the order is for 20 pieces, they are packed in one package (incl. 20 pieces).

[ ! ] See the details of degreasing, precision cleaning, and electrolytic polishing shown at the bottom of the

specification table.

specification table.Specification Table

| Part Number |

| SL-FRVG20A |

| SH-FRVGA40A |

| SHD-FRVG50A |

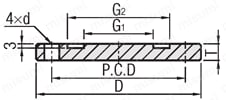

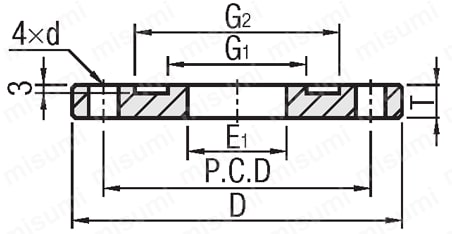

| Part Number | D | P.C.D | T | d | G1 | G2 | Hole Machined Type | Applicable O-Ring Size | |

| Type | No. | ||||||||

| E1 | |||||||||

| Blank Type SL-FRVG SH-FRVG SHD-FRVG Hole Machined Type SL-FRVGA SH-FRVGA SHD-FRVGA | 10 A | 70 | 50 | 8 | 10 | 24 | 34 | 17.8 | V24 |

| 20 A | 80 | 60 | 8 | 10 | 34 | 44 | 27.7 | V34 | |

| 25 A | 90 | 70 | 8 | 10 | 40 | 50 | 34.4 | V40 | |

| 40 A | 105 | 85 | 10 | 10 | 55 | 65 | 49.1 | V55 | |

| 50 A | 120 | 100 | 10 | 10 | 70 | 80 | 61.1 | V70 | |

Cleaning Process

Cleaning Process· Degreasing (Part Number: SL-□□)

Working Environment: General environment | ||||||

|---|---|---|---|---|---|---|

Hydrocarbon cleaning Ro water cleaning |  |  Wash with pure water after high-pressure water jet cleaning (Ro water) |  |  Use Oil-free Compressor |  |  Anti-rust single packing |

Working Environment: Class 1,000* | Working Environment: Class 10** | |||||||

|---|---|---|---|---|---|---|---|---|

Hydrocarbon cleaningRo water cleaning |  |  Wash with pure water (10 MΩ·cm) after high-pressure water jet cleaning (Ro water) |  |  Use pure water (13 MΩ·cm) |  |  Use nitrogen blow |  |  Conducted on a clean bench in a Class 10** clean environment |

**US FED STD 209E, ISO 14644-1 ISO 4 Equiv.

Working Environment: Class 1,000* | Working Environment: Class 10** | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Hydrocarbon cleaning Ro water cleaning |  |  Electrolytic polishing with an electrolytic polishing layer according to the material |  |  Wash with pure water (10 MΩ·cm) after high-pressure water jet cleaning (Ro water) |  |  Use warm pure water (13 MΩ·cm) |  |  Use nitrogen blow |  |  Conducted on a clean bench in a Class 10** clean environment |

**US FED STD 209E, ISO 14644-1 ISO 4 Equiv.

Packaging Example

Packaging Example| For degreasing: (Part Number: SL-□□)  Depending on some products and dimensions, packaging type may vary. | For precision cleaning or electrolytic polishing + precision cleaning: (Part Number: SH-□□/SHD-□□)  [ ! ] Both the first and second layer packaging are degassed. |

Cleaning Effectiveness / Recommended Environment for Use

Cleaning Effectiveness / Recommended Environment for UseCleaning Method | Product Part Number | Packaging Type | Effects Compared to Uncleaned Product | Environment (Standard) | Possible applications |

|---|---|---|---|---|---|

| Degreasing | SL-□□ | Anti-Rust Packing | Oil Removal | General Environment | Regular Assembly Process |

| Post Battery Assembly Process | |||||

| Precision Cleaning | SH-□□ | Degassing Double Packing | Oil Removal Dust Removal | Clean Environment (Class 10 to 1,000*) | Battery Assembly Process |

| LCD-Related Post Assembly Process | |||||

| In-Vehicle Camera Assembly Process | |||||

| Electrolytic Polishing + Precision Cleaning | SHD-□□ | Degassing Double Packing | Oil Removal Dust Removal Outgas Reduction | Vacuum Environment Clean Environment (Class 10 to 1,000*) | Pre-Semiconductor Process |

| Liquid Crystal Deposition Process | |||||

| Pre-OLED process |

Part Number:

- In order to open the 3D preview, the part number must be fixed.

3D preview is not available, because the part number has not yet been determined.

Basic information

| Type | Flange | Flange Type | VG | Material | EN 1.4301 Equiv. |

|---|---|---|---|---|---|

| Standard | JIS Standard | Same/Different Diameter | Same Diameter | Properties / applications | Clean washing |

| Environmentally Friendly | RoHS compliant (10 substances) | Material Details | EN 1.4301 Equiv. |

This page is [Clean & Pack]Fittings for Vacuum Plumbing - JIS Flanged, VG Type, part number SL-FRVGA25A.

You can find the detail information about specifications and dimensions on part number SL-FRVGA25A.

Configure

Basic Attributes

-

Type

- SH-FRVG

- SH-FRVGA

- SHD-FRVG

- SHD-FRVGA

- SL-FRVG

- SL-FRVGA

-

Flange Shape

- Standard

- Blank

-

Flange Size (Nominal)

- 10

- 20

- 25

- 40

- 50

-

Cleaning Method

- Degreasing

- Precision Cleaning

- Electrolytic polishing + precision cleaning

-

Filter by CAD data type

- 2D

- 3D

Filter by standard shipping days

-

- All

- 7 Days or Less

Optional Attributes

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Variation of this product

| Part Number |

|---|

| SH-FRVG25A |

| SH-FRVG40A |

| SH-FRVG50A |

| SH-FRVGA10A |

| SL-FRVGA40A |

| SL-FRVGA50A |

| Part Number | Standard Unit Price | Minimum order quantity | Volume Discount | Standard Shipping Days ? | Flange Shape | Flange Size (Nominal) | Cleaning Method |

|---|---|---|---|---|---|---|---|

52.72 € | 1 | 7 Days | Blank | 25 | Precision Cleaning | ||

69.39 € | 1 | 7 Days | Blank | 40 | Precision Cleaning | ||

71.86 € | 1 | 7 Days | Blank | 50 | Precision Cleaning | ||

47.96 € | 1 | 7 Days | Standard | 10 | Precision Cleaning | ||

70.92 € | 1 | 7 Days | Standard | 40 | Degreasing | ||

72.79 € | 1 | 7 Days | Standard | 50 | Degreasing |